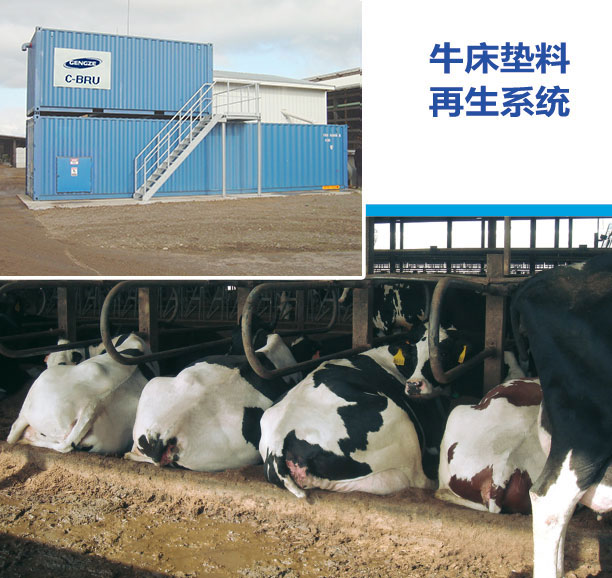

cattle- bedding recovery unit

Cotent:

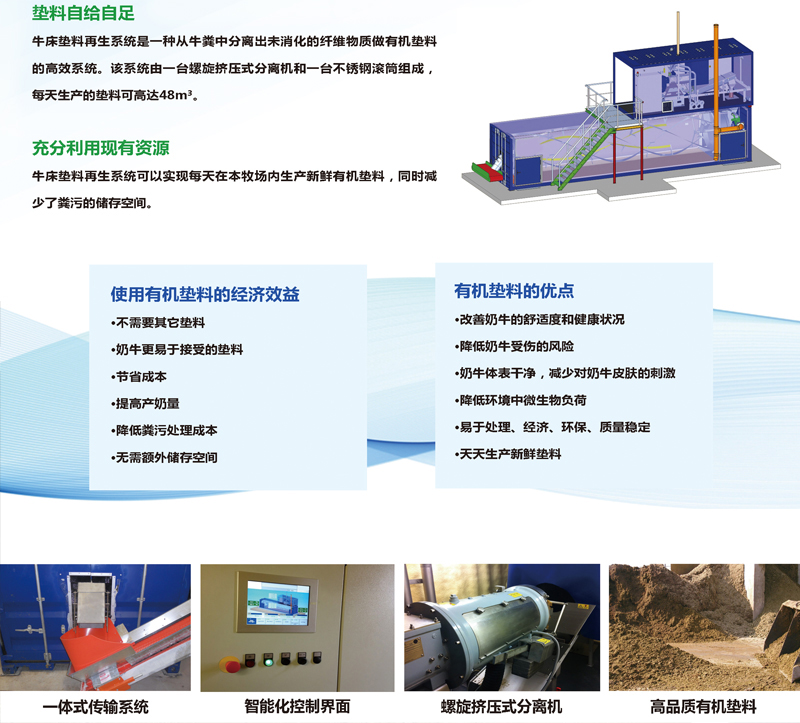

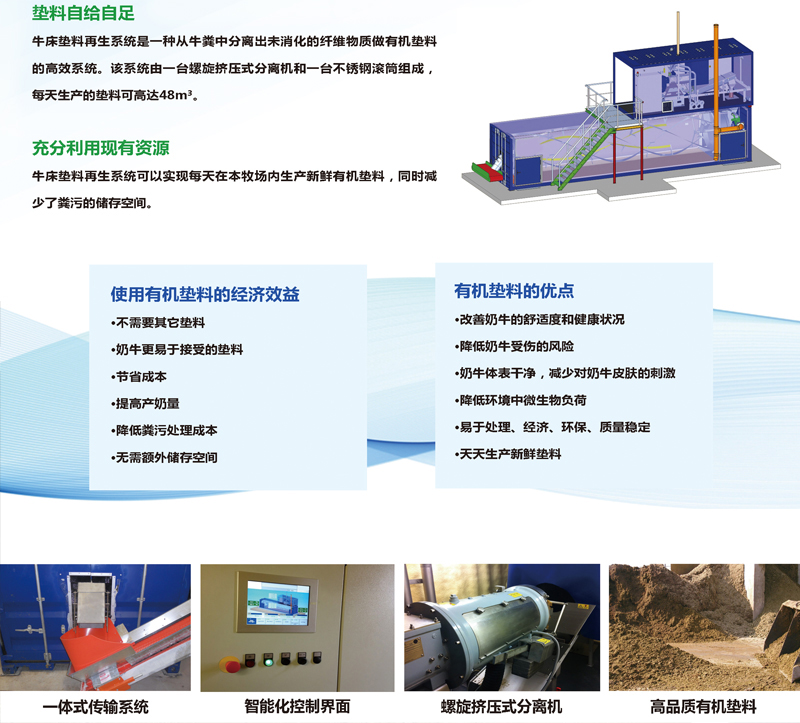

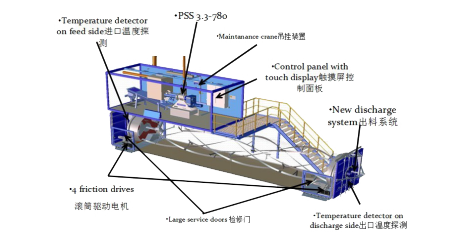

1ISO x 20 "container, used to completely isolated from the external environment temperature (the lowest isolation - 35 ℃), including:

●1 x PSS 3.3-780 screw extruder separator.

●Maintenance crane on top of container for maintenance of separator

●1 x separator outlet protection device, in the case of failure to automatically give a warning signal

●1 x switch cabinet, equipped with 10.4 "touch screen, can realize automatic control of cutting pump and agitator

●1 x material level controller: material level limit switch RN3002 has monitoring function and is made of stainless steel

●1 x ventilation fan, diameter 150mm, ventilating for container

●1 x screw conveyor with motor 1.5kw, cover plate at outlet, contacting parts made of 1.4301 (AISI 304) stainless steel

1 x ISO 40 "container, used to isolate the drum from the outside world and protect the aerobic fermentation inside the drum, including:

●4 x access door for easy access

●1 x feeding hopper made of stainless steel, used to feed materials into the drum of C-BRU

●1 x hot dip galvanized drum rack

●1 x full stainless steel drum, combined with specially improved delivery and transmission system

●4 x 1.1kw drive motor is used to drive the rotation of the drum

●2 x temperature sensor Pt100, for real-time monitoring of the temperature of the drum

●1 x fan, used to adjust the technological parameters of cushion material aerobic fermentation

Technical Features

(1)installation requirements:

it can be installed in the manure treatment plant, close to the sewage collection tank and the temporary storage tank.Workshope effected insulation treatment, ensures that the indoor temperature in the cold season is not less than zero degrees Celsius.The equipment covers an area of 15m 3.5m, and the recommended height of cornice is not less than 5.1m.

(2)technical parameters:

●Low temperature in the fermentating tank: 65-75 ℃

●Output: 48m3/d

●Fermentation time: 18-22h

●Dry material content of bedding 40%-42%

●Reduce up to 99% of harmful bacteria in the materials (tested by Shanghai animal disease prevention and control center: staphylococcus aureus and streptococcus agalactiae are zero in the bedding material, the total number of colonies is 3X105CFU, the MPN value of coliform group per gram <30, all within the permitted range).

(3)Processing technology:

Step 1: separate the coarse fiber (mainly undigested food such as corn, silage and hay) from the manure. The dry material content after separation is about 37~38%.

Step 2: solid aerobic treatment - harmlessness and drying. Temperature: 65-75 ℃, dry material content is 40-42%.

Advantage:

1) the drum is made of stainless steel

2) automatic weight control system

3) scraper on the inner wall of the drum to make the material more even

4) temperature control

5) container heat preservation can be used under the room temperature is 0 °

6) equipped with 2 or 4 friction driving wheels (2 for C-BRU 500, 4 for C-BRU 1000&2000

7) improve the comfort and health of cows

8) reduce labor costs and management costs

9) increase milk production

10) reduce storage space

11) no need to purchase additional bedding materials to reduce the cost